Processes

We have a wide range of modern and versatile production technologies.

Screen Printing

Screen printing involves applying ink directly to the surface of the material and then heat drying it to achieve permanent results. Graphics can include single color or multi-color printing and can customize inks based on Pantone color catalogs and can be customized.

Digital Printing

With their exceptional graphic detail and flexible inks, our Mimaki UV digital printers meet and exceed our customers' expectations in most environments, including high temperatures, high humidity and UV radiation.

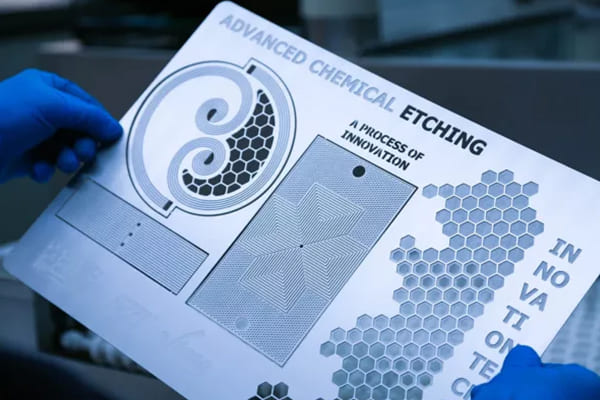

Etching

Chemical etching uses acids to etch a design onto the surface of a material to increase the durability and long-term readability of the part. Etching depth on a commercial label ranges from 0.040 microns” to 0.100 microns” depending on the height and stroke of the letters and the type of metal or alloy.

CNC Punching

CNC punching and cutting technology enables productive processing of sheet metal with the result of varied, combined and complex cutouts on one machine...

Laser Division

Sitapress uses its fiber lasers to cut individual labels while reducing lead times, reducing material waste and maintaining tight tolerances. Laser cutting helps us always provide high quality parts.

Laser Engraving

Every product you produce must have an identity or more importantly identification. It helps companies improve their quality systems and manage their production processes. Therefore, we can provide you with a numbering service based on your specific needs. The numbering on the labels can be embossed, laser engraved, chemically etched or anodized.

Lamination